Sync Series Steam Turbine Generators

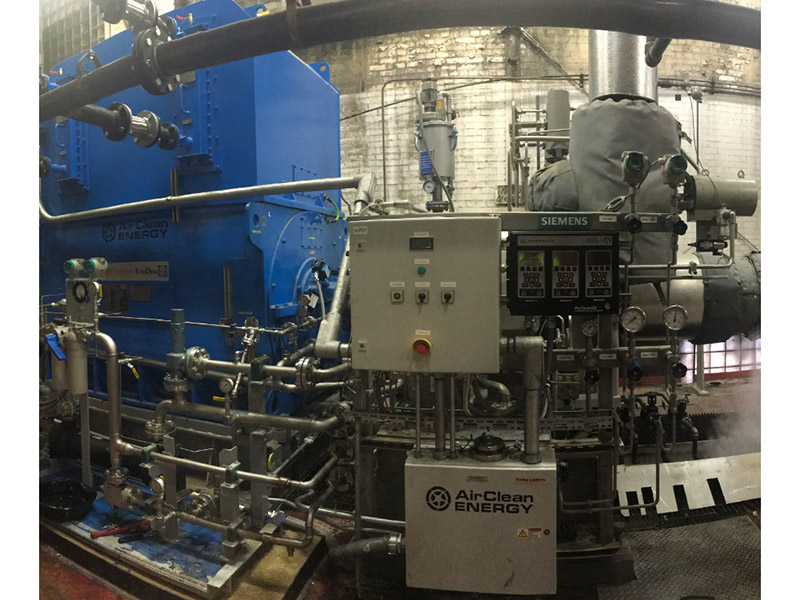

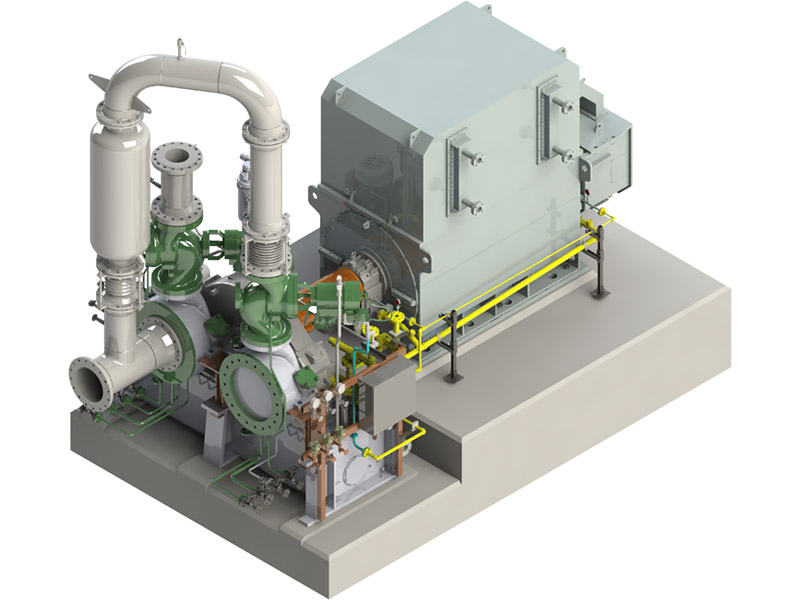

Steam turbine and gear-reduced synchronous generator

Looking for More Options in a Steam Turbine Generator?

If you want to produce power when you reduce your steam pressure, a steam turbine generator can provide the ideal solution to meet your needs. For steam systems with higher flow or efficiency requirements which preclude Indy Series STG’s, AirClean’s Sync Series STG’s will fulfill your needs. The Sync Series offers higher turbine efficiency than the Indy Series by adding a gearbox between the turbine and the generator. This allows the turbine speed to be optimized for maximum power production. In addition, AirClean uses a synchronous generator for the Sync Series rather than an induction generator. While an induction unit can only be used parallel with the grid, a synchronous steam turbine generator can also operate in isolation.

Is An AirClean Energy Sync Series STG Right For You?

AirClean Energy Sync Series STG’s offer superior efficiency and control to the Integral Induction STG’s. Like the induction model, the synchronous generator is engineered for peak performance, long-life, and low-maintenance operation. These units come in two distinct flavors: Coupled Gearbox (CG) and Integral Gearbox (IG).

- Sync-CG (Coupled Gearbox) STG’s are the older siblings to the Indy Series STG’s. These skid-mounted units consist of a steam turbine, reduction gear, synchronous generator and turbine generator control system. They share similar form factor and utility requirements as the Indy Series with broader capabilities.

- Sync-IG (Integral Gearbox) STG’s stand apart from the Sync-CG’s in terms of power output and efficiency. These units can handle much larger steam flows than the Sync-CG’s or the Indy Series. Their unique turbine/gearbox design gives them efficiencies which are competitive with small multi-stage turbines with simpler commissioning and maintenance. They can be configured with a single turbine wheel (Sync-IG-1) or two wheels (Sync-IG-2) when especially large flows or mid-pressure steam extraction is required.

Our Sync Series STG’s are customized for your facility. Packaged for easy installation, they include control systems designed for intuitive operator interaction and use PLC-based monitoring systems for vibration, temperature and overspeed trips. In most cases, our systems pay for themselves within two to five years.

-

- Technical Specifications

- Typical Utility Requirements

- Brochure

Sync-CG Sync-IG-1 Sync-IG-2 Power Generation Capacity: Up to 2,500 kWe Up to 6,000 kWe Up to 7,000 kWe Generator Voltages: 480 VAC / 4,160 VAC / 13,500 VAC 480 VAC / 4,160 VAC / 13,500 VAC 480 VAC / 4,160 VAC / 13,500 VAC Power Factor: Set between 0.4 and 1.0 Set between 0.4 and 1.0 Set between 0.4 and 1.0 Steam Inlet Pressures: Up to 900 psig Up to 1900 psig Up to 1900 psig Steam Inlet Temperature: Up to 900°F Up to 950°F Up to 950°F Footprint: 7’ x 14’ (typical) 15’ x 25’ x 15’ tall (typical) 15’ x 25’ x 15’ tall (typical) Weight: 14,000 lb (typical) Turbine – 20,000 lb, Generator – 35,000 lb Turbine – 28,000 lb, Generator – 35,000 lb Sync-CG Sync-IG-1 Sync-IG-2 Turbine Bearing Lubrication Type: Ring-oiled or force-lubricated / ISO VG 68 Integral force-lubrication / ISO VG 46 Integral force-lubrication / ISO VG 46 Turbine Bearing Cooling Water: 2 gpm / 100 psig (max) / 90°F (max) 70 gpm / 50 psig (max) / 95°F (max) 70 gpm / 50 psig (max) / 95°F (max) Generator Lubrication Type: Anti-friction grease 100 gpm / 30 psig (max) / 95°F (max) 100 gpm / 30 psig (max) / 95°F (max) Generator Coil Cooling Water: None Oil, 12.5 gpm / 215 psig Oil, 12.5 gpm / 215 psig Throttle Control Fluid: Air, 45 psig – 125 psig (integrated with oil lubrication system) (integrated with oil lubrication system) Control Panel Power: 120 VAC / 1 Ph / 60 Hz / 20 A 120 VAC / 1 Ph / 60 Hz / 30 A 120 VAC / 1 Ph / 60 Hz / 30 A Synchronous Steam Turbine Generators