Engine and Gas Turbine Heat Recovery

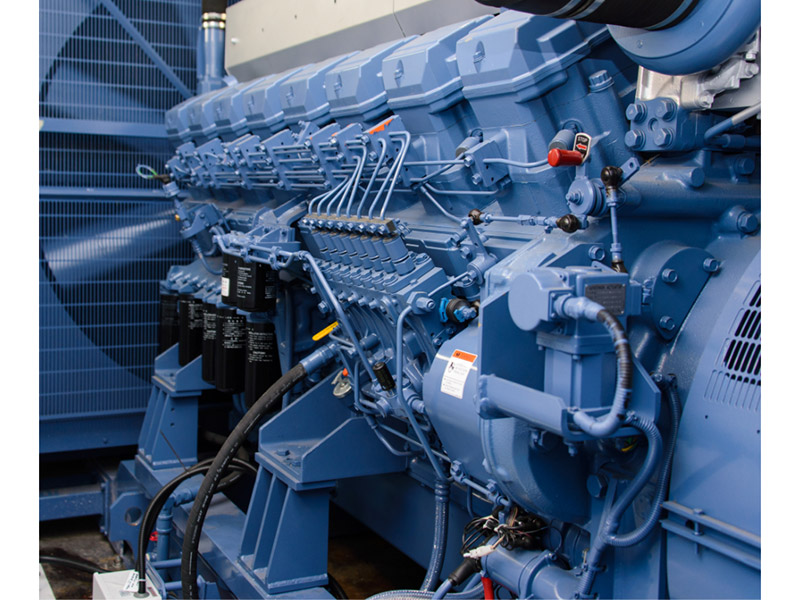

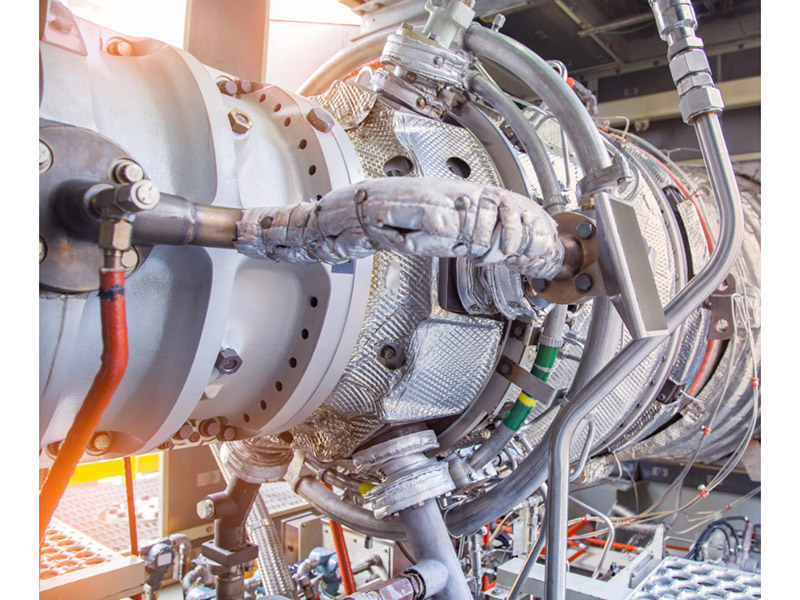

Enhanced Energy Production with a Fast Payback

Reciprocating engines and gas turbines have low thermal efficiency when operating without heat recovery. The low thermal efficiency (typically 45% for engines and 35% for gas turbines) result in high exhaust gas temperatures. The lower the efficiency the higher the exit gas temperature, therefore gas turbines tend to be very good opportunities for adding heat recovery. To increase heat recovery on reciprocating engines, jacket water cooling can be integrated into the heat recovery. Power generation from heat recovery can add 7-10% output at no additional fuel cost. In areas with high power cost and/or high fuel cost, the extra power can be very valuable. Typical payback for a ‘bottoming cycle’ heat recovery for either engines or gas turbines is less than 5 years.

Increased efficiency with multiple engines in parallel

Often gas turbines and engines operate multiple units in parallel. There can be a benefit to ducting the exhaust of multiple sources into a common boiler or heat recovery device to improve the economics of the project. AirClean can provide the optimized design, resulting in highest value for the project. We will do the complete design, including bypass system(s) and equipment design, with a full wrap-around guarantee so that you have a comprehensive solution that provides the payback you need.

As an industry leading innovator in waste heat recovery, AirClean Energy is highly experienced and fully equipped to develop a custom engine and gas turbine heat recovery solution to meet your needs.